AC Compressor Repair: Costs, Signs of Failure & Repair Options

The heart of your cooling system is the component that circulates refrigerant, allowing your air conditioner to cool your home effectively. When this critical part fails, it can lead to a significant increase in energy bills and even cause the entire system to shut down.

A failing compressor can manifest through various symptoms, including unusual noises, leaks, or a noticeable decrease in cooling performance. Understanding these signs is crucial for prompt action.

Whether you’re dealing with a minor issue or a complete failure, knowing your air conditioning repair options and the associated costs can help you make an informed decision.

Key Takeaways

- Recognizing the signs of a failing compressor to prevent further damage.

- Understanding the costs associated with different types of repairs.

- Exploring DIY fixes versus professional replacement options.

- Learning preventative maintenance tips to extend the compressor’s lifespan.

- Determining when to repair versus replace the compressor based on cost-effectiveness.

Understanding Your AC Compressor

Understanding the compressor’s function is essential for maintaining an efficient air conditioning system. The compressor is a critical component that directly impacts the overall performance of your cooling system.

What Is an AC Compressor and How Does It Work?

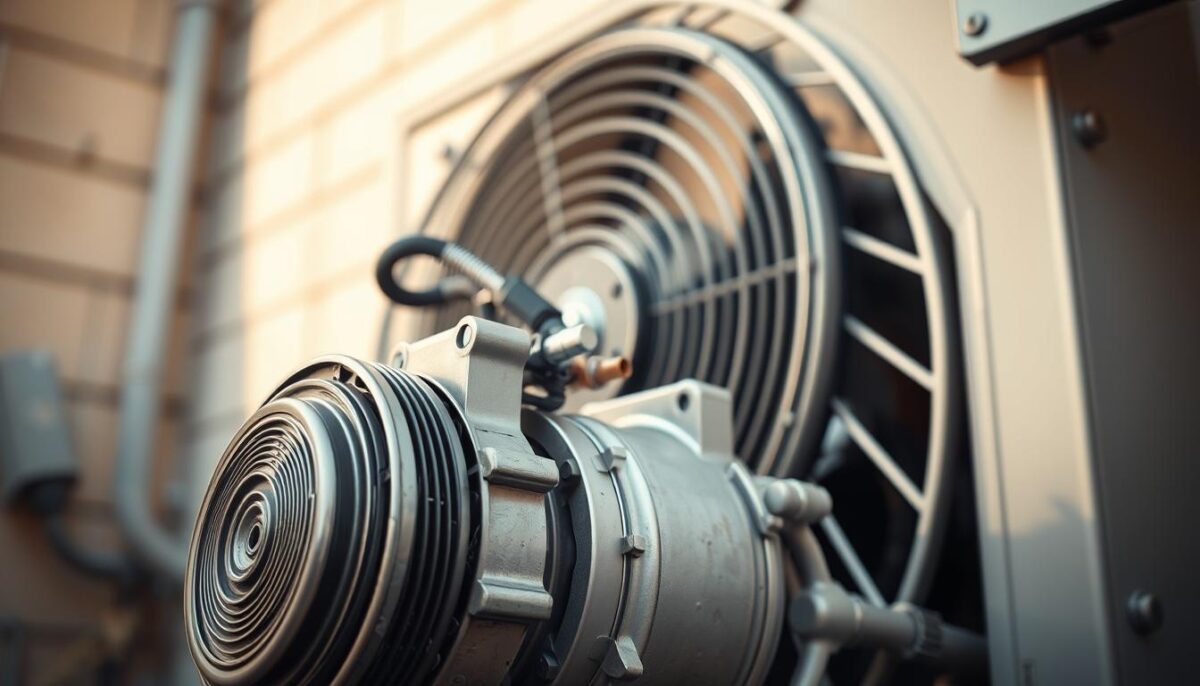

The AC compressor is a vital component located outside the air conditioning unit. It is responsible for circulating refrigerant through the coils of both indoor and outdoor equipment, facilitating heat exchange. Contrary to popular belief, the compressor generates heat as part of the cooling process by compressing refrigerant gas.

Key Functions of the AC Compressor:

- Circulates refrigerant through the system’s coils

- Facilitates heat transfer from inside to outside

- Maintains optimal pressure in the system

- Works in conjunction with other key components like the condenser, evaporator, and expansion valve

Why the Compressor Is Critical to Your Cooling System

The compressor is often considered the heart of the air conditioning system due to its crucial role in pressurizing refrigerant and facilitating heat exchange. A properly functioning compressor ensures efficient cooling and prevents potential system failures.

| Compressor Type | Efficiency Level | Description |

|---|---|---|

| Reciprocating | Medium | Traditional compressor type with moving parts |

| Rotary | High | More efficient with fewer moving parts |

| Scroll | High | Known for quiet operation and high efficiency |

| Variable Speed | Very High | Adjusts speed according to cooling demand |

7 Common Signs of AC Compressor Failure

Identifying the early warning signs of AC compressor failure can save you from unexpected breakdowns and costly repairs. Your air conditioning system’s compressor is a critical component, and its failure can lead to a cascade of issues affecting the overall performance and efficiency of your cooling system.

Unusual Noises Coming From Your Unit

One of the first indicators of a potential issue with your AC compressor is unusual noises emanating from the outdoor unit. Sounds such as clicking, rumbling, or rattling can signal internal mechanical problems within the compressor. These noises are often a sign that the compressor’s components are wearing out or have become misaligned.

Reduced Cooling Performance

If your air conditioning system is running constantly but failing to cool your space effectively, it could be a sign of compressor failure or declining efficiency. Reduced cooling performance is a classic symptom that warrants further investigation into the compressor’s condition.

System Blowing Warm Air

When your air conditioning system blows warm air instead of cool air, it may indicate that the compressor isn’t properly circulating refrigerant through the system. This issue can lead to increased energy bills and reduced system performance.

Frequent System Cycling

Frequent cycling, or the repeated turning on and off of the AC system, suggests that the compressor is struggling to maintain proper pressure levels. This can be due to a variety of issues, including refrigerant leaks or internal compressor problems.

Visible Damage or Leaks

Visible refrigerant leaks around the outdoor unit are a clear indication of compressor or condenser coil issues that require immediate attention. Leaks can lead to a decrease in system performance and an increase in energy consumption.

The following table summarizes the common signs of AC compressor failure:

| Sign | Description |

|---|---|

| Unusual Noises | Clicking, rumbling, or rattling sounds indicating internal mechanical issues |

| Reduced Cooling Performance | System running constantly but failing to cool effectively |

| System Blowing Warm Air | Compressor not circulating refrigerant properly |

| Frequent System Cycling | Compressor struggling to maintain proper pressure levels |

| Visible Damage or Leaks | Refrigerant leaks indicating compressor or condenser coil issues |

DIY AC Compressor Troubleshooting Steps

DIY troubleshooting of your air conditioning compressor involves a series of simple checks that can help identify the problem. Begin by verifying the AC system’s operation and ensuring it has the proper power supply.

Checking Power Supply and Circuit Breakers

Start by examining the switches in your breaker box. Ensure the switch for the air conditioner’s circuit is in the correct position and that none of the switches are oriented differently from the others. If your system isn’t receiving enough power, try switching the breaker to the off position and then back on again.

Inspecting the Condenser Unit

Next, inspect the outdoor condenser unit for any visible damage, debris, or obstructions that might be affecting airflow around the compressor. Clean the area around your outdoor unit to ensure at least 2 feet of clearance for proper air circulation and heat dissipation.

Testing Airflow and Temperature

Test the airflow from vents inside your home to determine if the issue is with air distribution rather than the compressor itself. Check and replace the air filter if it’s clogged, as restricted airflow can cause the system to work harder and stress the compressor.

When to Stop DIY Efforts and Call a Professional

If basic troubleshooting doesn’t resolve the problem, it’s time to call a professional. Never attempt to handle refrigerant or internal compressor repairs without proper certification, as these require specialized tools and knowledge. Document all troubleshooting steps you’ve taken to provide valuable information to the technician if professional service becomes necessary.

Professional AC Compressor Repair Options

Understanding the professional repair options for your AC compressor can help you make informed decisions about your cooling system. Professional technicians have the expertise and specialized tools to diagnose and fix complex issues with your AC compressor.

Compressor Motor Repair

Professional compressor motor repair often involves diagnosing electrical issues, replacing worn bearings, or rebuilding the motor assembly. Technicians must carefully assess the motor’s condition to determine the most cost-effective and efficient repair solution.

Refrigerant Recharge and Leak Repair

Refrigerant recharge services include proper evacuation of the system, leak detection using specialized equipment, and precise refrigerant charging to manufacturer specifications. This ensures that your AC system operates efficiently and effectively, while also complying with environmental regulations.

Electrical Component Replacement

Electrical component replacement may include capacitors, contactors, or relays that can fail before the compressor itself needs replacement. Technicians will inspect these components and replace them if necessary to ensure the compressor operates correctly.

Full Compressor Replacement Process

During a full compressor replacement, professionals will also replace associated components like the expansion valve, orifice tube, and receiver dryer. Before removing the old compressor, they will carefully drain all refrigerant to prevent environmental damage and comply with EPA regulations.

Key steps in the repair process include: – Diagnosing the root cause of the compressor failure – Cleaning the air conditioning system of all foreign substances – Replacing damaged or worn-out components – Ensuring proper refrigerant levels and charging – Testing the system under pressure to ensure all connections are secure and leak-free By choosing professional AC compressor repair services, you can ensure that your cooling system is restored to optimal performance while minimizing the risk of future failures.

AC Compressor Repair Costs Explained

The financial impact of AC compressor repairs can range from minor expenses to major investments. Understanding these costs is crucial for homeowners to make informed decisions about their air conditioning systems.

Minor Repairs: $150-$400 Range

Minor AC compressor repairs typically fall within the $150-$400 range. These repairs often include electrical component replacement, refrigerant top-offs, and basic diagnostic services. Such fixes are usually sufficient for addressing minor issues before they escalate into more significant problems.

Major Repairs: $500-$1,200 Range

Major repair costs can range between $500-$1,200. These repairs often involve partial compressor rebuilds, extensive refrigerant leak repairs, or addressing significant electrical issues. The complexity and cost of parts replacement contribute to the higher cost.

Full Compressor Replacement: $1,300-$2,500 Range

Full compressor replacement represents the most expensive option, with costs ranging from $1,300 to $2,500. This cost varies based on the unit size, brand, and accessibility. The age of the air conditioner and its overall condition play significant roles in determining whether a replacement is justified.

Factors That Influence Repair Costs

Several factors influence AC compressor repair costs. Labor costs, which typically account for 30-50% of total repair expenses, can vary significantly by geographic location and time of year. The age of the air conditioner and manufacturer warranty coverage also play crucial roles in determining the final cost. Emergency service calls, especially during peak summer months, can increase costs by 25-50%.

- Labor costs account for 30-50% of total repair expenses

- Units over 10 years old may not justify expensive compressor repairs

- Manufacturer warranty can reduce replacement costs within the covered period

- Emergency service calls can increase costs by 25-50%

Repair vs. Replace: Making the Right Decision

Compressor failure presents a critical decision for homeowners: whether to repair or replace the entire AC system. This decision involves considering several key factors that can significantly impact the efficiency, reliability, and cost-effectiveness of your cooling system.

Age of Your AC System

The age of your air conditioner plays a crucial role in determining whether to repair or replace it. Typically, air conditioners have a lifespan of 10-15 years. For systems over 10 years old, compressor replacement may be less economical due to potential compatibility issues and the approaching end of the system’s lifespan.

Cost-Benefit Analysis

Conducting a cost-benefit analysis is essential. The “50% rule” is a useful guideline: if repair costs exceed half the price of a new system, replacement is usually the more economical choice. Additionally, consider the frequency of recent repairs; multiple issues within a short timeframe often indicate a system nearing the end of its useful life.

Energy Efficiency Considerations

Modern replacement systems offer significantly improved efficiency ratings, potentially reducing energy costs by 20-40% compared to units 10+ years old. Newer systems may also qualify for utility rebates, tax credits, or other incentives that can offset replacement costs.

Warranty Coverage Factors

Manufacturer warranty terms should be carefully reviewed. Many manufacturers offer 5-10 year coverage on compressors, but may require proof of annual maintenance. Understanding your warranty coverage can significantly influence your decision.

| Factor | Repair | Replace |

|---|---|---|

| System Age | Suitable for newer systems | Recommended for systems over 10 years old |

| Cost | Potentially lower upfront cost | Higher initial cost, but potential long-term savings |

| Efficiency | Maintains current efficiency level | Significantly improved efficiency with new systems |

Preventing Future AC Compressor Problems

Preventing future AC compressor problems requires a combination of regular maintenance and smart usage habits. To keep your air conditioning system running efficiently, it’s crucial to adopt practices that reduce strain on the compressor.

Regular professional maintenance is key to preventing compressor issues. Scheduling a spring tune-up can help identify potential problems before they become major issues. Additionally, changing air filters monthly during heavy use periods maintains proper airflow and reduces strain on the compressor. Keeping the outdoor condenser unit clean and free of debris is also vital, as is maintaining at least 2 feet of clearance around it to ensure adequate air circulation.

Using programmable thermostats can help avoid excessive cycling and maintain consistent temperatures, reducing compressor wear. It’s also advisable to avoid setting the thermostat extremely low during extreme heat, as this forces the compressor to work harder than necessary. Consider installing a compressor saver or hard-start kit, especially for older systems, to reduce strain during startup.

By following these tips and scheduling annual professional maintenance with a qualified service team, you can significantly extend the life of your AC compressor. Keeping contact information for a reliable service team handy ensures prompt response when issues arise.