Tankless vs Traditional Water Heater: Which Is Better for Arizona Homes?

Arizona’s unique climate presents specific challenges for water heating systems, making the choice between tankless and traditional water heaters particularly important for homeowners.

Traditional water heaters store and continuously heat a large tank of hot water, while tankless systems heat water on demand as it flows through the unit.

Arizona’s extreme summer temperatures and typically hard water can significantly impact heater performance and longevity.

This comprehensive guide will help Arizona homeowners understand the key differences, costs, and benefits of both water heater types.

Key Takeaways

- Understand the key differences between tankless and traditional water heaters.

- Learn how each system performs in Arizona’s climate.

- Discover the costs and benefits associated with both types.

- Determine which water heater type is best suited for your household’s needs.

- Consider factors such as initial costs, long-term savings, and space requirements.

Understanding Water Heater Options for Arizona Homes

Arizona’s climate is known for its extreme heat and hard water, factors that significantly impact the performance and longevity of water heaters. Choosing the right water heater involves understanding these challenges and how different systems can meet them.

The Importance of Choosing the Right Water Heater in Arizona’s Climate

The right water heater can lead to significant energy savings and improved performance in Arizona’s challenging conditions. Arizona’s extreme climate, with temperatures often exceeding 100°F, creates unique challenges for water heating systems.

Incoming water temperature is a critical factor; warmer incoming water can affect the sizing and efficiency calculations for both tankless and traditional water heaters.

How Arizona’s Hard Water and Heat Impact Water Heater Performance

Arizona’s hard water contains high mineral content, which can cause scale buildup in water heaters. This buildup can reduce efficiency and lifespan, particularly affecting tankless systems.

| Factor | Impact on Traditional Water Heaters | Impact on Tankless Water Heaters |

|---|---|---|

| Hard Water | Scale buildup can reduce efficiency | More susceptible to scale buildup, affecting performance |

| High Temperatures | Must work harder to maintain temperature in hot environments | Can be more efficient in high demand situations |

Understanding these factors is crucial for selecting a water heater that meets your household’s needs while minimizing potential drawbacks.

Tankless vs Traditional Water Heater: Key Differences

The choice between tankless and traditional water heaters for Arizona homes depends on understanding their distinct operational characteristics and benefits. Both types of water heaters have unique features that cater to different household needs and preferences.

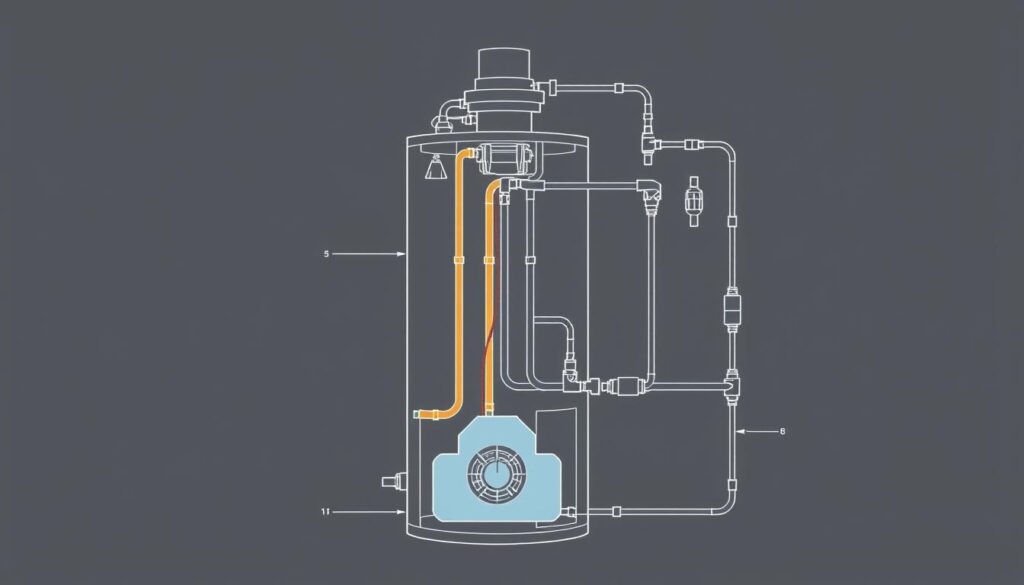

How Traditional Tank Water Heaters Work

Traditional tank water heaters operate by storing a significant amount of water (typically between 40-80 gallons) in an insulated tank and maintaining it at a preset temperature around the clock. These systems utilize either gas burners or electric heating elements to heat the water, with thermostats controlling the temperature and safety valves preventing excessive pressure buildup. As hot water is used, cold water enters the tank to replace it, triggering the heating system to maintain the set temperature.

Key characteristics of traditional tank water heaters include:

- Storage capacity ranging from 40 to 80 gallons

- Continuous heating to maintain the set temperature

- Potential for standby heat loss

How Tankless Water Heaters Function

In contrast, tankless water heaters, also known as “on-demand” water heaters, heat water only when there is a demand for it. They use high-powered burners or electric elements to rapidly heat water as it flows through the unit. Tankless systems typically employ flow sensors to detect when a hot water tap is opened, instantly activating the heating elements to warm the water to the desired temperature.

| Characteristics | Traditional Tank Water Heaters | Tankless Water Heaters |

|---|---|---|

| Storage Capacity | 40-80 gallons | No storage tank |

| Heating Mechanism | Gas burners or electric elements | High-powered burners or electric elements |

| Energy Efficiency | May suffer from standby heat loss | No standby heat loss |

| Hot Water Supply | Finite amount of hot water | Theoretically endless hot water |

Understanding these key differences is essential for Arizona homeowners to make an informed decision that suits their household’s hot water needs and preferences.

Pros and Cons of Traditional Water Heaters for Arizona Homes

When it comes to choosing a water heating system, Arizona homeowners often consider traditional water heaters as a viable option. Traditional water heaters have been widely used in Arizona homes, and their pros and cons are essential to understand before making a decision.

Advantages of Traditional Water Heaters

Traditional water heaters offer several benefits to Arizona homeowners. One of the primary advantages is their lower initial cost and simpler installation. The water heater installation process is generally less complicated and requires fewer modifications to existing plumbing and gas lines, making it a more cost-effective option upfront.

Lower Initial Cost and Simpler Installation

Traditional water heaters are typically priced between $400-$900, significantly lower than tankless water heaters, which can cost $1,000-$3,000. The simpler installation process also reduces labor costs, making traditional water heaters an attractive option for many homeowners.

Reliable Performance During Peak Usage

Traditional water heaters excel at handling high-demand situations, providing consistent hot water for multiple simultaneous uses like showers and dishwashing. This reliability is particularly beneficial for larger Arizona households where hot water demand can be high.

Disadvantages of Traditional Water Heaters

Despite their advantages, traditional water heaters also have several drawbacks. One significant disadvantage is their higher energy consumption in hot climates. In Arizona’s hot climate, traditional water heaters constantly maintain water temperature, even when not in use, leading to higher utility bills.

Higher Energy Consumption in Hot Climates

The standby heat loss is particularly problematic when tanks are installed in hot Arizona garages, where ambient temperatures increase energy consumption. This inefficiency can result in higher energy bills over time.

Space Requirements and Maintenance Needs

Traditional water heaters require significant space (approximately 16-20 square feet) and regular maintenance, including flushing to remove sediment buildup from Arizona’s hard water. The typical lifespan of 8-12 years is also shorter than tankless alternatives, meaning more frequent replacements.

Pros and Cons of Tankless Water Heaters for Arizona Homes

When considering a water heating solution for Arizona homes, it’s essential to weigh the pros and cons of tankless water heaters. Tankless water heaters are becoming increasingly popular due to their numerous benefits, but they also have some drawbacks that need to be considered.

Advantages of Tankless Water Heaters

Tankless water heaters offer several advantages for Arizona homeowners. They are more energy efficient and can provide significant savings on utility bills.

Energy Efficiency and Lower Utility Bills

Tankless water heaters heat water only when needed, resulting in energy savings of up to 24-34% compared to traditional tank water heaters when daily hot water usage is less than 41 gallons. This efficiency can translate to annual savings of $100-$200 on utility bills for Arizona homeowners.

Space-Saving Design and Longer Lifespan

The compact design of tankless water heaters saves valuable space in homes, taking up to 80% less space than traditional tanks. Additionally, tankless systems can last 20+ years with proper maintenance, outlasting traditional tanks which typically last 8-12 years.

Disadvantages of Tankless Water Heaters

Despite their advantages, tankless water heaters also have some significant drawbacks. These include higher upfront costs and potential limitations in meeting simultaneous hot water demands.

Higher Upfront Costs

The initial purchase and hot water heater installation costs of tankless water heaters are substantially higher than traditional water heaters, with units costing $1,000-$3,000 and installation adding another $1,000-$2,000.

Potential Output Limitations

A single tankless water heater may struggle to meet the simultaneous hot water demands of larger households, potentially requiring multiple units for families with high usage patterns.

| Feature | Tankless Water Heaters | Traditional Water Heaters |

|---|---|---|

| Energy Efficiency | Up to 24-34% more efficient | Less efficient |

| Lifespan | 20+ years | 8-12 years |

| Space Requirements | Up to 80% less space | More space required |

| Initial Cost | $1,000-$3,000 + installation | Generally lower upfront cost |

Installation and Cost Considerations

Arizona homeowners must weigh the installation costs and long-term benefits when deciding between tankless and traditional water heaters. The choice between these two options involves understanding the installation process, associated costs, and how they impact the overall efficiency and savings.

Traditional Water Heater Installation in Arizona Homes

Installing a traditional water heater in Arizona typically costs between $500-$1,000. The process is relatively straightforward, requiring minimal modifications to existing plumbing systems, and can be completed in 2-3 hours by a professional plumber.

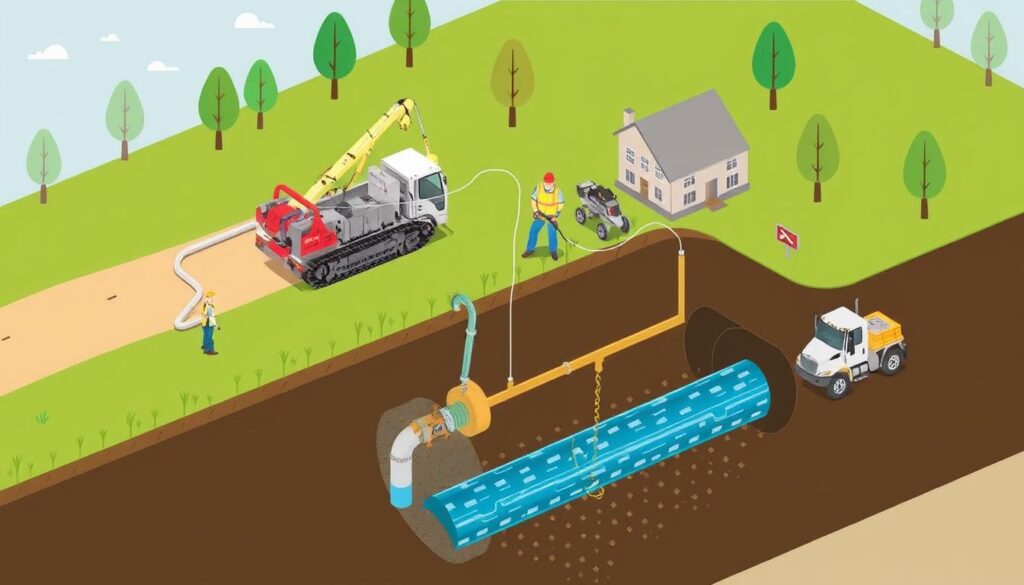

Tankless Water Heater Installation Requirements

Tankless water heater installation costs range from $1,000-$2,500 in Arizona, with installation times of 4-8 hours depending on complexity. These installations often require electrical upgrades or larger gas lines and new venting, adding to the overall cost.

Long-Term Cost Analysis for Arizona Homeowners

The long-term cost analysis favors tankless systems despite higher upfront costs, with potential break-even points occurring after 5-10 years of operation in Arizona homes. Energy savings from tankless systems are more pronounced in Arizona due to the elimination of standby heat loss.

Evaluating Your Home’s Needs

When it comes to choosing between a tankless and traditional water heater, understanding your home’s specific needs is crucial. This involves assessing several key factors that influence the performance and suitability of your water heating system.

Assessing Your Household Size and Hot Water Usage

The size of your household and your hot water usage patterns are critical in determining the right water heater for you. Larger families or households with multiple simultaneous hot water users may require a larger traditional tank or multiple tankless units. Consider your peak usage times and the number of appliances that use hot water.

- Larger Arizona families may need a larger traditional tank or multiple tankless units.

- Analyzing peak hot water usage helps determine the appropriate system capacity.

Considering Your Current Plumbing System

Your existing plumbing configuration can significantly impact the installation costs and feasibility of either a tankless or traditional water heater. Older homes may require updates to accommodate tankless systems, while homes with limited space can benefit from the compact design of tankless units.

Energy Efficiency Goals and Environmental Concerns

If energy efficiency and environmental concerns are a priority for you, consider that tankless water heaters are generally more efficient and have a smaller carbon footprint. They can provide long-term savings and are a more environmentally friendly option. Additionally, Arizona’s rebate programs and tax incentives can offset the higher upfront costs of tankless systems.

- Tankless systems have improved efficiency and a longer lifespan.

- Arizona’s rebate programs can make tankless systems more financially attractive.

Making the Right Choice for Your Arizona Home

The decision betweentanklessand traditionalwater heatersdepends on several factors specific to your Arizona home. To make an informed decision, it’s essential to consider your household size, hot water usage, and long-term plans. For instance,Arizona homeswith 1-2 residents may benefit from atankless systemdue to its energy efficiency and long-term value.

When evaluating your options, consider factors such as space constraints, energy efficiency priorities, and budget. If you plan to stay in your home for 7+ years, the energy savings from atankless water heatercan offset the higher initial investment. It’s also crucial to consider Arizona’s hard water and its impact on yourwater heater. Consulting with a qualified plumber who specializes in Arizona installations, like those atCamcor Plumbing, can help you navigate these considerations and choose the bestwater heating systemfor your needs.

Ultimately, the right choice will depend on your specific circumstances. By carefully evaluating your needs and consulting with a professional, you can make an informed decision that meets your hot water demands and enhances your home’s efficiency.